Electrical safety is a critical aspect of any electrician’s job. The dangers involved with working with electricity require not just skill and focus but also the appropriate safety gear. A key part of that safety gear is the use of electrical gloves, which are designed to protect the hands from electrical shocks and burns. Understanding the significance of electrical gloves is the first step in establishing safe work practices that prevent accidents and injuries on the job.

These gloves are an integral part of Personal Protective Equipment (PPE) for electricians, and complement other safety and workwear components. It is essential to recognize how electrical gloves work in unison with items such as safety glasses, face shields, and electrician backpacks, to provide a comprehensive safety solution for those working in hazardous electrical environments.

Understanding Electrical Gloves Classifications for Safety

| Category | Details |

|---|---|

| Significance of Electrical Gloves | Essential for protecting against electrical shocks and burns; integral part of electricians’ Personal Protective Equipment (PPE). |

| Glove Classifications | Provide reference for the type of gloves needed based on voltage level; standardized from Class 00 (up to 500V AC) to Class 4 (up to 36,000V AC). |

| Class 00 and Class 0 Gloves | For low voltage work up to 1,000V AC; flexible and suitable for tasks like residential electrical work and computer repairs. |

| Class 1 and Class 2 Gloves | Designed for medium voltage up to 17,000V AC; used in commercial and industrial maintenance and installation of electrical components. |

| Class 3 and Class 4 Gloves | High voltage protection up to 26,500V AC and 36,000V AC respectively; necessary for power transmission and handling of high-voltage equipment. |

| Care and Maintenance | Include regular inspections, storage away from sunlight, and cleaning with mild soap; essential for the longevity and effectiveness of the gloves. |

| Selecting the Right Gloves | Consider maximum voltage protection, material, and required dexterity; similar to selecting other tools like leaf blowers. |

| Compliance and Certification Standards | Adherence to standards such as ASTM D120 is crucial for safety and reliability; certification instills trust in the product’s protective qualities. |

| Conclusion | Electricians must prioritize safety by selecting the correct gloves and supporting their work with reliable tools and workwear. |

| Further Resources | Guides on using electrical tools and reviews, such as how to use a voltage tester pen and the Bosch GOP18V-34N 18V Multi-Tool review. |

Remember to always match your protective equipment with the tools and voltage levels you’ll be working with to maintain a safe working environment.

Classifications of Electrical Gloves: An Overview

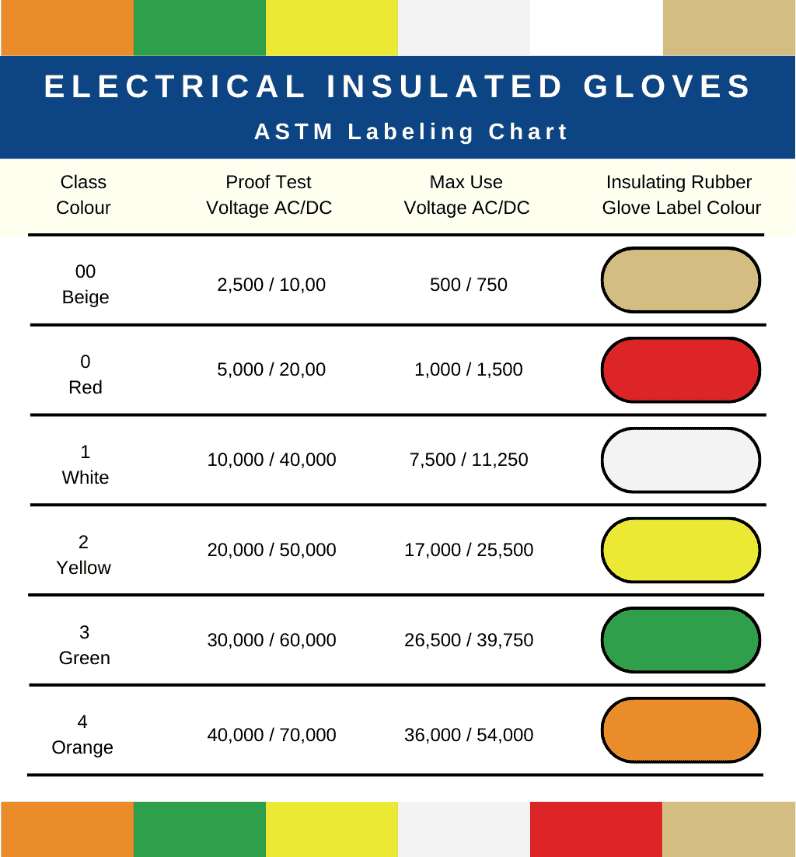

The role of glove classifications in ensuring electrical safety cannot be overstated. These classifications provide electricians with an easy reference to determine what type of gloves they need based on the voltage level they will be working with. The classification system used for electrical gloves is a standardized guide that indicates the maximum voltage against which the gloves can protect. This system ensures that electricians are equipped with the necessary level of protection for their specific work tasks.

Understanding the basics of this classification system is crucial in selecting the appropriate gloves for the job at hand. This foundation is vital for both seasoned professionals and those just beginning their careers in the electrical field, as it directly impacts their safety and the safety of their surroundings.

Detailed Breakdown of Electrical Gloves Classifications

Electrical gloves are categorized by their ability to withstand certain voltage levels without compromising the safety of the person wearing them. The classifications range from Class 00, which is suitable for lower voltages, up to Class 4, designed for high-voltage environments. Each classification corresponds to a specific voltage level, making it easier to match the gloves to the intended application.

Here is a list of glove classes and their specific voltage protections:

- Class 00: Up to 500 volts AC

- Class 0: Up to 1,000 volts AC

- Class 1: Up to 7,500 volts AC

- Class 2: Up to 17,000 volts AC

- Class 3: Up to 26,500 volts AC

- Class 4: Up to 36,000 volts AC

Class 00 and Class 0 Gloves: Low Voltage Protection

When working with low voltage systems, electricians often rely on Class 00 and Class 0 gloves. These gloves provide adequate protection for tasks where the voltage does not exceed 1,000 volts AC. Class 00 gloves are designed for the lowest exposure levels and are generally more flexible, allowing for greater dexterity during intricate tasks.

Ideal scenarios for using low voltage gloves include residential electrical work, computer repairs, and telecommunications projects. When paired with the best voltage tester, these gloves ensure that electricians can safely and effectively conduct their work while protected from electrical hazards.

Class 1 and Class 2 Gloves: Medium Voltage Protection

Class 1 and Class 2 gloves are built to safeguard electricians who are regularly exposed to medium voltage levels. These gloves are designed to withstand voltages up to 17,000 volts AC, providing a significant level of insulation and protection. The characteristics that set Class 1 and Class 2 gloves apart include their thicker design, which allows for increased safety at the expense of some tactile sensitivity.

The usage of these gloves can be found in:

- Commercial electrical work

- Industrial equipment maintenance

- Installation of electrical components

Class 1 and Class 2 gloves are commonly employed in everyday electrical tasks that fall within their voltage protection ratings, ensuring worker safety in a variety of medium voltage situations.

Class 3 and Class 4 Gloves: High Voltage Protection

In high voltage environments, the necessity for greater hand protection becomes paramount. Class 3 and Class 4 gloves are the robust companions for electricians facing such conditions. These gloves can shield against voltages up to 26,500 volts AC and 36,000 volts AC, respectively, providing the highest level of insulation in the electric glove classification spectrum.

Tasks that require Class 3 and Class 4 gloves include:

- Power transmission and distribution

- High-voltage power generation

- Handling of high-voltage cables and equipment

For instance, when using a high-voltage tool like the DeWALT 20V MAX XR Impact Driver, having gloves with the appropriate classification is not just recommended, it is critical for safety.

Care and Maintenance of Electrical Gloves

The proper care and maintenance of electrical gloves are essential to ensure their longevity and maintain their protective qualities. By following a regular maintenance routine, electricians can rely on their gloves to provide consistent protection over time. This includes frequent inspection for any signs of physical damage, wear, or degradation.

Storage, inspection, and cleaning tips include:

- Keep gloves in a cool, dry place away from direct sunlight

- Inspect gloves before each use for tears, punctures, or signs of wear

- Clean gloves with mild soap and water, and air dry them thoroughly before storage

Caring for electrical gloves shares similarities with the maintenance of other workwear, such as work boots, in that they both require regular inspection and proper storage to maintain their protective properties.

Selecting the Right Electrical Gloves for the Job

When choosing electrical gloves, several factors must be considered to ensure they are well-suited for the work environment and voltage level with which an electrician will be dealing. Some of these factors include the maximum voltage protection required, the glove’s material and construction, and the necessary level of dexterity for the task.

In a similar vein to selecting other tools, like leaf blowers, where factors like power, ease of use, and ergonomics are weighed, picking the right pair of electrical gloves requires a balance between safety and practicality.

Compliance and Certification Standards for Electrical Gloves

To ensure the safety and reliability of electrical gloves, they must meet certain compliance and certification standards. One of the key standards is ASTM D120, which sets the requirements for the design, testing, and use of insulating gloves. Adhering to these standards is not just about due diligence—it’s a crucial aspect of professional safety and responsibility for electricians.

The importance of these certifications is also about trust. When electricians don gloves that have been tested and certified, they are placing their safety in the hands of the manufacturers who have committed to meet or exceed these stringent guidelines.

Conclusion

The critical nature of correctly classified electrical gloves for electricians cannot be overstressed. These specialized gloves are an essential line of defense against electrical hazards. It is paramount for electricians to prioritize safety above all, selecting the right gloves, and supporting their daily protective practices with curated and reliable hand tools, power tools, and workwear from trusted sources.

Always remember to pair the right equipment with the right protection to ensure the safety of electricians industry-wide. Make safety a habit and work with confidence, knowing that you are well-protected by your carefully chosen gear.

Further Resources

For more information and practical guides, explore the “how-to” sections with topics like how to use a voltage tester pen and insights into how stud finders work. For reviews on the latest tools, check out the detailed analysis of the Bosch GOP18V-34N 18V Multi-Tool and a roundup of the top 5 reciprocating saws to ensure you have the right companion for your protective handwear.