In the realm of fastening and assembly, the Torx screwdriver is an unsung hero. Its innovative design offers a unique solution to many of the challenges faced by conventional screwdrivers. This guide takes you through the world of Torx screwdrivers, unveiling the benefits they bring to professionals and DIY enthusiasts alike. We’ll cover what a Torx screwdriver is, its advantages, its applications in various industries, and tips on how to choose, use, and maintain your Torx screwdrivers.

Understanding the Torx Screwdriver

The Torx screwdriver is a specialized tool often used in professional and DIY settings for its ability to apply high torque without damaging the driver or screw head. Here’s a summarized table of the key elements covered in our comprehensive guide.

| Aspect | Details |

|---|---|

| Design | Six-point star-shaped pattern, designed for high torque and reduced cam-out. |

| History | Developed in the 1960s by Camcar Textron, now a staple in many industries. |

| Advantages | Increased torque transmission, reduced wear, and improved safety. |

| Sizes and Variations | Available from sizes T1 to T100+, with standard, security, and precision variations. |

| Key Factors when Choosing | Size variety, material quality, and ergonomic design of the screwdriver set. |

| Common Uses | Electronics, automotive, construction, machinery assembly, and more. |

| Maintenance | Cleaning, storage best practices, and regular upkeep to extend tool life. |

What is a Torx Screwdriver?

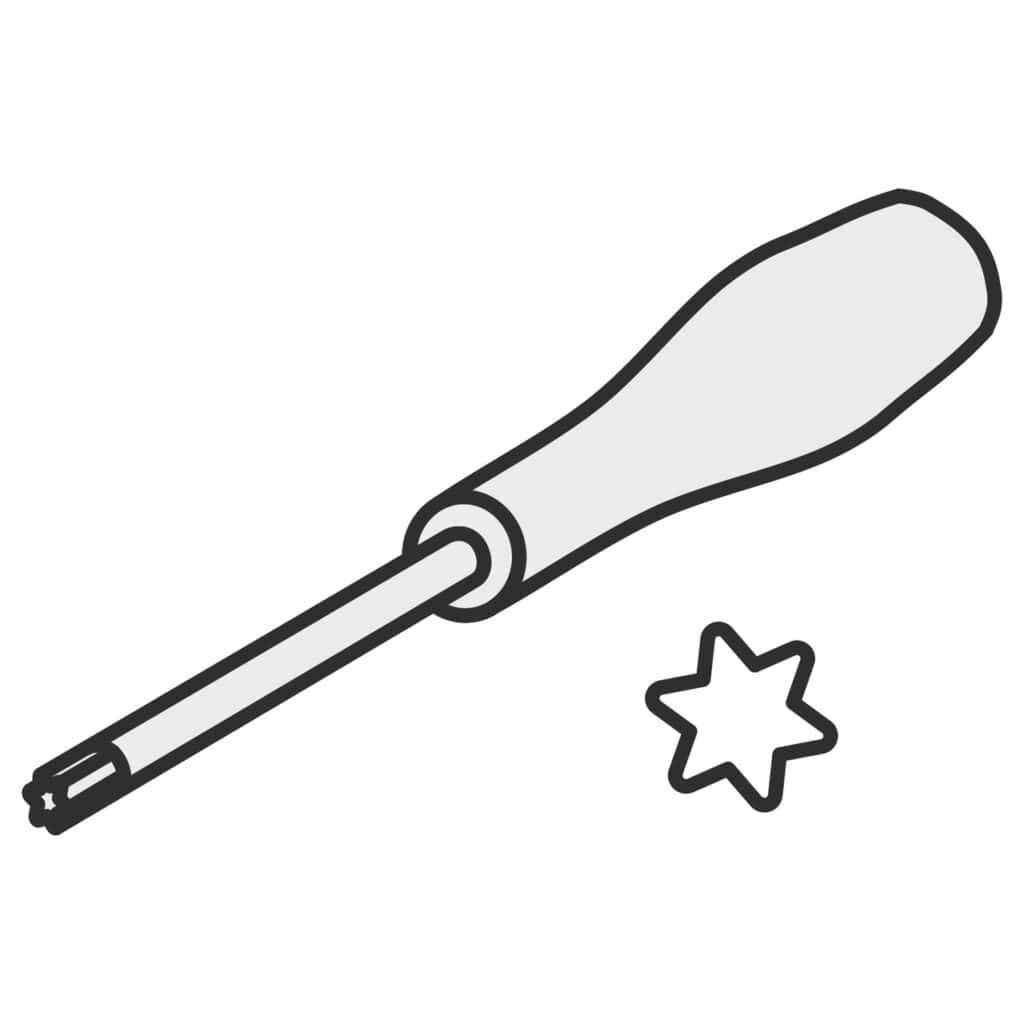

The Torx screwdriver, characterized by its six-point star-shaped pattern, is a specialized tool created to ensure a high degree of torque transfer between the screwdriver and screw. This design also reduces the risk of cam-out, the slippage that can occur with standard flat or Phillips head screwdrivers under high torque application. The name ‘Torx’ itself has become synonymous with this pattern, which is also referred to as a star bit.

A Brief History of the Torx Screwdriver

The Torx design was developed in the 1960s by Camcar Textron. It was originally created to provide a more reliable solution for high-torque situations, which were increasingly common in manufacturing industries. Since its inception, the Torx design has been adopted in various applications, becoming a favorite among professionals in fields ranging from automotive to consumer electronics.

Also read: 623-483-04 Screws

Recognizing the Torx Design

The appearance of the Torx head is distinctive, marked by its symmetrical star-shaped socket. This precise shape allows for exact fitment with the corresponding Torx screwdriver or bit, thereby ensuring better transmission of force and reducing wear.

Advantages of Using a Torx Screwdriver

The obvious benefit of a Torx system is its ability to handle higher torque without damaging the driver or screw. This property makes it invaluable in situations that require a tight fastening, such as in automotive or machinery assembly.

Improved Torque Transmission

- Provides a large contact area between screw and driver.

- Allows for more torque to be applied without damaging the screw.

- Offers greater precision in tasks requiring detailed torque specification.

Reduced Wear and Cam-out

- Torx’s design inherently reduces the risk of the driver slipping out from the screw head, known as cam-out.

- It extends the lifetime of both tools and fasteners.

- Torx promotes a safe work environment by minimizing the chance for injury caused by slippage.

Types of Torx Screwdrivers

Not all Torx tools are created equal. The variety available ensures that there is a specific Torx screwdriver for nearly every application.

Different Sizes of Torx Screwdrivers

Torx screwdrivers come in an array of sizes, denoted as T1, T2, etc., up to T100 or higher. The number corresponds to the distance between opposite points of the star-shaped bit.

Also read: Rotary Drill vs. Hammer Drill

Variations: Standard, Security, and Precision

- Standard Torx drivers are the most common and are suitable for general use.

- Security Torx feature a post in the center of the star pattern, requiring a corresponding hole in the driver tip.

- Precision Torx are designed for fine work common in electronics repair and small mechanics.

- The T-Range Explained:

- T5, T10, and T30 are among the most commonly used sizes.

- T5 is often used in electronics, T10 in automotive work, and T30 in construction.

- Specialty Torx Tools for Particular Industries:

- Some industries require proprietary Torx sizes to maintain exclusivity or meet specialized requirements.

Selecting the Best Torx Screwdriver Set

- [PRECISON TORX SCREWRIVERS]:This is a multipurpose star screwdriver repair tool kit which include T2 T3 T4 T5 torx screwdriver and T6 T7 T8 T9 T10 T15 torx security screwdiver with a hollow in the tips. Complete and compact mini torx screwdrivers set.

- [WIDELY APPLICATIONS]: Widely used for Apple macbook, iphone, xbox controller,PS3,PS4,laptop,computer, game consoles,Mac mini,pocket knife,ring doorbell,dishwashers,shavers,routers and many electronic devices with torx screws.

- [MAGNETIC MINI TORX SET]: All magnetic screwdriver bits make it perfect to hold and handle tiny screws in case of missing or dropping, very strong magnetized tips.

- [CONSTRUCTION]: The precision screwdriver bits are made of good S2 steel, specially hardened with heat treatment, durabl aN high quality for long time use. Ergonomic design and comvenient to use in hand.

- [NON-SKID FLEXIBLE HANDLES]: The long handle is made of TPR and PP material which is non-skid with flexible cap, easy and pretty comfortable to grip in hand and convenient to use for different kinds of electronic repairs.

- Made of Chrome vanadium steel with heat treatment,high hardness, large torque, long service life.

- Cushion grip handle for comfort and control,With ergonomic TPR handle and button on it, it helps you to use easily.

- Black finish blade with magnetic tips which could conveniently attracts screws.

- Set Includes: T5 x2-1/2", T6 x2-1/2", T7 x 2-1/2", T8 x 2-1/2", T9 x 2-1/2", T10 x 2-1/2", T15 x 4", T20 x 4", T25 x 4", T27 x 4", T30 x 4", T40 x 5"and a magnetic retriever .

- Widely used for maintenance and assembly of all kinds of mechanical equipment ,domestic appliances and furniture.

- [Security Torx Screwdriver Bit Set]: TEKPREM 13-piece torx bit set with driver handle include T4 T5 normal torx bit and TR6 TR7 TR8 TR9 TR10 TR15 TR20 TR25 TR27 TR30 TR40 security torx bits set.

- [Industrial Grade S2 Steel Bits]: All the torx bits are made of industrial grade S2 steel, high quality and sturdy for long time use.Precise and accurate to fit and remove your torx screws with no hassle.

- [Strong Magnetic Bit Driver]:This set also include a strong magnetic bit driver handle, it will not only hold short screwdriver bits tightly and firmly but also magnetic to grip the screws. MOST OF THE OTHER 1/4 inch screwdriver handle can only hold the bits but NON-MAGNETIC TO HOLD SCREWS

- [Widely Applications]: The T4-T40 torx bits set can be widely used for engines,automobiles,motorcycles,bicycle,Stihl chainsaws,trucks,furniture and other equipments with torx screws.

- [All Bits in One]: All the bits are stored in a rubber strip which are convenient for storage and pick up.

- Torx/star screwdriver set is Chrome vanadium steel with heat treatment, high hardness and good toughness and resistance,large torque, long service life.

- Black finish blade with magnetic tips which could conveniently attracts screws.

- Cushion grip handle for comfort and control,With ergonomic TPR handle and button on it, it helps you to use easily.

- Set Includes: T8*60MM,T10*60MM,T15*100MM,T20*100MM,T25*100MM,T27*100MM,T30*100MM.

- Torx/star screwdrivers are widely used for maintenance and assembly of all kinds of mechanical equipment ,domestic appliances and furniture.

- 【Precision screwdriver set】-- 24Pcs precision screwdriver set includes 20Pcs CRV screwdriver bits which are phillips +1.5(PH000) +2.0(PH00) +3.0(PH0), flathead -1.0 -1.5 -2.0, torx T1 T2 T3 T4 T5, torx security TR6 TR8 TR9 TR10 TR15, triwing Y0.6(Y000) Y1.5(Y00), pentalobe 0.8(P2) 1.2 (P5), with a screwdriver handle, a double-ended spudger, a triangle spudger, and a SIM card thimble.

- 【Wide application】-- P2 Y0.6 +1.5 +2.0 are used for iPhone 7/8/X/XR/11/12/13, for their screens and batteries replacement only. T8 +1.5 +2.0 +3.0 are used for PS3/PS4/PS5. T6 T8 T10 are used for Xbox 360/Series S&X. Y1.5 +1.5 +2.0 are used for Switch/Joy-Con/Wii. T6 T15 are used for Ring Video Doorbell/Video Doorbell 2/Pro/Elite. T8 is suitable for Folding knife. T3 T5 T6 T8 +1.5 +2.0 P5 are used for Macbook Air and Pro. -1.0 -2.0 +1.5 +2.0 +3.0 are used for Computer/ Watch/Glasses.

- 【Slip-resistant rotatable handle】-- The screwdriver handle is made of TPR and PP materials, with a special non-slip design, offering a sense of comfortable. The top of the handle is rotatable design which makes it more convenient to remove the screws; the handle head has magnetic adsorption which can quickly replace the screw head.

- 【CR-V screwdriver bits】-- All our screwdriver bits are made of high quality CR-V chrome vanadium steel. CR-V screwdriver bits do not rust easily and are not prone to be worn out.

- 【Portable gadgets】-- The triangular spudger is more suitable for opening the screen of the mobile phone.The double-ended spudger is more suitable for opening the back cover of game devices. The SIM card thimble can be used to replace the SIM card of the mobile phone.

When in search of the perfect Torx set, several factors come into play, including the tasks at hand and the environments in which they will be used.

Key Factors to Consider

- The variety of Torx sizes included.

- The quality of the materials used for longevity.

- Ergonomic design for comfort during extended use.

Comparison of Top Sets on the Market

Given the saturation of the market with varying qualities of tools, a little research is essential.

- Compatibility with Various Screw Sizes: Ensure the set covers all sizes you’re likely to encounter in your work.

- The Importance of Handle Grip and Material Quality: Good grip decreases fatigue and increases accuracy. Also, the material quality directly influences the durability of the screwdriver.

Armed with this information, you can make informed decisions about incorporating Torx screwdrivers into your toolkit, ensuring each task is approached with the right equipment for efficiency and effectiveness. Remember to consult our best tool box recommendations when organizing your Torx screwdrivers and other essential hand tools for a complete and professional setup.

1 thought on “Torx Screwdriver: A Comprehensive Guide”