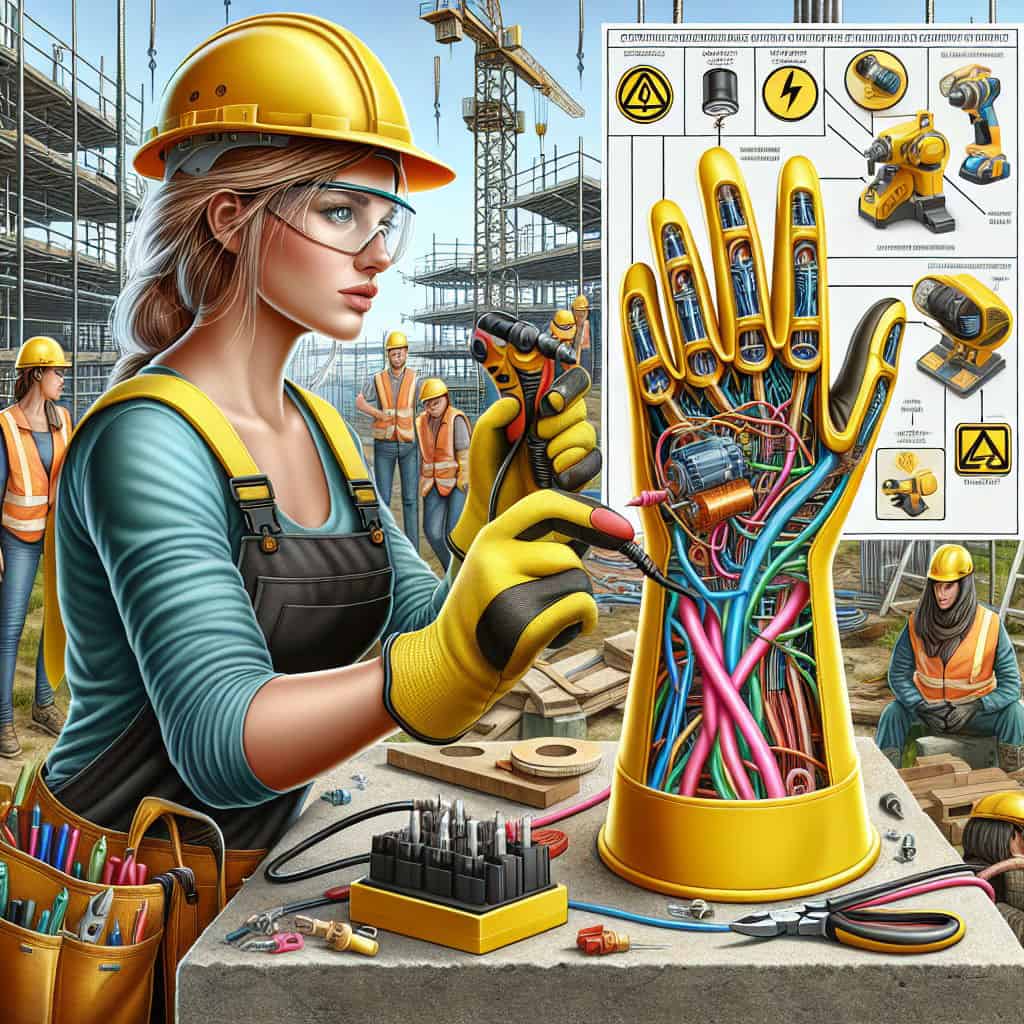

Working with electricity requires not only skill and precision but also the right safety equipment to protect from electrical hazards. High voltage gloves are a critical component of an electrician’s safety gear, designed specifically to provide insulation and protect against electric shock. These gloves are manufactured to withstand specified voltage levels, ensuring that electricians can safely work on or near live circuits and equipment.

| Key Takeaways: High Voltage Gloves for Electrical Safety |

|---|

| Essential Protection |

| – High voltage gloves are crucial for insulating against electric shocks and protecting electricians. |

| – They are the first defense against electrocution, making them a non-negotiable safety item. |

| – Classes range from 00 to 4, offering protection from 500 to 36,000 volts, respectively. |

| Materials and Types |

| – Typically made from rubber and silicone for insulation and flexibility. |

| – Leather protectors are combined with rubber gloves for additional mechanical protection. |

| Selection Criteria |

| – Consider voltage level, dexterity, comfort, fit, and environmental resistance. |

| – Compare brands for additional features such as ergonomic design and enhanced dexterity. |

| Testing and Maintenance |

| – Gloves require regular testing, ideally every six months, for integrity checks. |

| – Use a voltage tester to ensure gloves are free from damage or wear. |

| – Inspect, clean, and store gloves correctly to maintain their protective qualities. |

| Complementary Safety Gear |

| – Combine high voltage gloves with work footwear and an electrician backpack for complete protection. |

| Tool Efficiency |

| – Reviews like Bosch GOP18V-34N 18V Multi-Tool Review and DeWalt 20V MAX XR Impact Driver Review (DCF845) guide tool selection. |

| – The right hand and power tools enhance safety and work efficiency. |

| Safety First |

| – Continuous learning and staying updated with safety protocols is mandatory. |

| – Proactive prevention and preparedness are the best safety measures. |

| Further Resources |

| – Explore Hand Tools, Power Tools, and Workwear for additional safety and efficiency tips. |

| – Learn more with guides like How to Use a Voltage Tester Pen and How Stud Finders Work. |

This table encapsulates the essential elements and best practices regarding high voltage gloves for electrical safety to ensure electricians operate in a safe environment while enhancing their efficiency and preparedness for any electrical work.

The significance of high voltage gloves in the context of electrical work cannot be overstated. They serve as the first line of defense against electrocution, which can lead to serious injury or even death. It is of utmost importance that every electrician understands the role of protective gear and makes it a non-negotiable aspect of their daily routine.

Types of High Voltage Gloves

When it comes to manufacturing high voltage gloves, various materials are used to achieve the necessary levels of insulation and durability. The most common materials include rubber, which provides excellent dielectric properties, and silicone, known for its flexibility and moisture resistance. Leather protectors are often used in conjunction to rubber gloves for mechanical protection against abrasions and punctures.

High voltage gloves are classified into different types based on the level of voltage protection they offer. These classes are determined by American Society for Testing and Materials (ASTM) standards and range from Class 00, which provides protection up to 500 volts, to Class 4, which is suitable for working with voltages up to 36,000 volts.

How to Select the Right High Voltage Gloves

Choosing the correct high voltage gloves is critical for ensuring maximum protection. Several factors must be considered to make an informed decision:

- The voltage level of the electrical work being performed

- Dexterity requirements

- Comfort and fit

- Resistance to environmental elements such as oil or ozone

It is also invaluable to compare different brands and their specific offerings to determine which gloves meet both the safety standards and personal preferences of the electrician. Top brands in the industry often provide additional features like increased dexterity or ergonomic design.

The Importance of Proper Glove Testing

High voltage gloves, like any other piece of safety equipment, require regular testing to ensure their integrity and protective qualities are maintained. The standard testing interval for electrical gloves is every six months, although this can vary depending on the usage and company policy.

Testing gloves involves checking for punctures, tears, and signs of aging or wear. A voltage tester is a vital tool used in the process, designed to detect weak spots where the insulation might fail. ASTM F1236 outlines the standard guide for the visual inspection of electrical protective rubber products, which includes gloves.

Maintenance and Care for High Voltage Gloves

Maintaining high voltage gloves is essential for ensuring their longevity and reliability. Follow these tips and best practices:

- Regularly inspect gloves before and after each use

- Clean them with mild soap and water, avoiding petroleum-based products

- Dry at room temperature away from direct sunlight and heat sources

Proper storage is also crucial. Store gloves in a protective bag or container free from sharp objects or conditions that could compromise the material, such as extreme temperatures or ozone exposure.

Complementary Safety Gear for Electrical Work

While high voltage gloves are vital, they are part of a larger suite of safety gear necessary for electrical work. A comprehensive safety setup includes matched items such as reliable work footwear that is insulated and rated for electrical hazards. Moreover, owning a robust electrician backpack ensures your gloves and other essential tools are organized, protected from damage, and always within reach.

Enhancing Work Efficiency with Proper Tools

Having the right high voltage gloves is part of the equation for safety, but efficiency in electrical work also highly depends on the quality and suitability of the tools being used. In-depth reviews like the Bosch GOP18V-34N 18V Multi-Tool Review and the DeWalt 20V MAX XR Impact Driver Review (DCF845) help electricians make informed choices for their toolkit.

These tools offer other advantages:

- Enhanced speed and precision in cutting, drilling, and fastening

- Cordless convenience for easier maneuverability in tight spaces

- Durable construction for prolonged use in varied electrical tasks

Conclusion: Emphasizing Electical Safety

The crucial nature of high voltage gloves in the safety repertoire of an electrician is undeniable. They are not just tools but lifelines that prevent tragic accidents and allow professionals to go home safely at the end of the day. Continuous learning, adherence to safety protocols, and staying abreast of the latest in electrical safety can not be optional for anyone in this field.

Always remember that the best safety measure is a proactive approach towards prevention and preparedness.

Resources and Further Reading

For more insights and resources in the electrical domain, delve into related categories such as Hand Tools, Power Tools, and Workwear. Expand your knowledge with additional tips and guides like How to Use a Voltage Tester Pen and How Stud Finders Work, to ensure both safety and efficiency in all your electrical endeavors.