A well-equipped workshop is the foundation of successful DIY projects and repairs. Whether you’re fixing a broken chair or building custom furniture, having the right tools at your disposal makes all the difference in achieving professional results.

| Key Aspect | Description |

|---|---|

| Safety First | Always prioritize proper safety equipment |

| Quality Matters | Invest in durable, reliable tools |

| Organization | Keep tools accessible and well-maintained |

| Essential Categories | Hand tools, power tools, measuring tools |

| Budget Planning | Start with basics, expand gradually |

Hand Tools: The Foundation of Every Workshop

The backbone of any workshop starts with reliable hand tools. These timeless implements have stood the test of time and remain essential even in our power tool-dominated era.

Basic Hand Tool Arsenal

- A quality 16-oz claw hammer for general use

- Multiple screwdrivers including Phillips and flathead varieties

- Adjustable wrenches for versatile fastening needs

- Precision pliers for detailed work

Measuring and Marking Tools

Accurate measurements are crucial for successful projects. Here’s what you need:

Essential Measuring Equipment

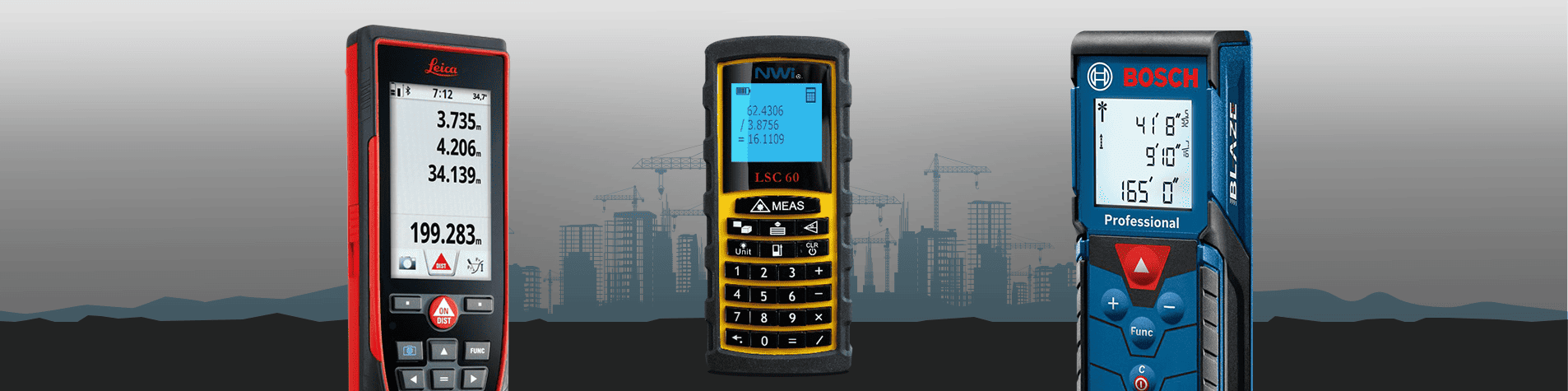

- Digital laser measure for precise distances

- Traditional tape measure as backup

- Combination square for perfect angles

- Spirit level for ensuring proper alignment

Power Tools: The Game Changers 🔌

Modern workshops benefit enormously from power tools that speed up work and improve precision.

Must-Have Power Tools

- Cordless drill with multiple settings

- Angle grinder for cutting and shaping

- Reciprocating saw for demolition work

- Electric screwdriver for quick assembly

Safety Equipment ⚠️

Never compromise on safety gear. Your workshop needs:

Personal Protection

- Impact-resistant safety glasses

- Work gloves appropriate for the task

- Hearing protection for loud power tools

- Hard hat for overhead work

Storage Solutions 🗄️

Proper tool storage extends tool life and improves workflow efficiency. Consider:

Storage Options

- Heavy-duty toolbox for portable tools

- Wall-mounted pegboard for frequently used items

- Drawer organizers for small tools

- Mobile tool cart for convenience

Workshop Setup Tips

Creating an efficient workspace requires thoughtful organization:

Workspace Optimization

- Install adequate lighting

- Maintain clear walkways

- Position power tools near outlets

- Create dedicated zones for different tasks

Remember that building a workshop is an ongoing process. Start with the basics and gradually add tools as your skills and project needs expand. For specialized tasks, consider tools like precision tool sets or specific power tools based on your most common projects.## Specialty Tools and Advanced Equipment 🔧

Building on our foundation, let’s explore the specialized tools that take your workshop capabilities to the next level.

Advanced Tool Selection

- Digital multimeters for electrical work

- Bench vises for secure workpiece holding

- Soldering stations for electronics projects

- Air compressors for pneumatic tools

Modern Workshop Technologies

Today’s workshops benefit from cutting-edge tools and techniques that enhance precision and efficiency.

Digital Integration

- 3D printing capabilities for custom parts

- CNC machining for precise fabrication

- Digital measuring tools with Bluetooth connectivity

- Laser levels for perfect alignment

Consumables and Accessories

A well-stocked workshop needs more than just tools:

Essential Supplies

- Various grits of sandpaper

- Multiple types of adhesives

- Assorted fasteners (screws, nails, bolts)

- Cutting fluids and lubricants

Maintenance and Care

| Tool Type | Maintenance Frequency | Key Care Points |

|---|---|---|

| Hand Tools | Monthly | Clean, oil, inspect |

| Power Tools | After each use | Check cords, lubricate |

| Measuring Tools | Quarterly | Calibrate, clean |

| Safety Equipment | Weekly | Inspect, replace as needed |

Workshop Environment Control

Creating the right environment extends tool life and improves work quality:

Environmental Factors

- Temperature control systems

- Proper ventilation setup

- Dust collection systems

- Adequate humidity control

Project Planning Station

Every workshop needs a dedicated area for planning and reference:

Planning Essentials

- Work surface for drawings

- Reference material storage

- Computer station for research

- Material sample storage

Emergency Preparedness

Safety goes beyond protective gear:

Emergency Setup

- First aid station

- Fire extinguisher

- Emergency shut-off switches

- Eyewash station

Advanced Tips for Workshop Efficiency

Workflow Optimization

- Keep frequently used tools within arm’s reach

- Install adequate power outlets

- Use mobile tool stations

- Label storage clearly

For specialized projects, consider investing in task-specific tools like heat guns for detail work or precision voltage testers for electrical projects.

Future-Proofing Your Workshop

Stay ahead with these considerations:

Workshop Evolution

- Plan for tool upgrades

- Allow space for expansion

- Consider new technologies

- Budget for improvements

Remember that a workshop is a living space that evolves with your skills and project needs. Regular maintenance, thoughtful organization, and strategic upgrades will keep your workshop productive and efficient for years to come. For specific tool recommendations and detailed guides, explore our comprehensive power tool guides and hand tool reviews.