Electricians face numerous hazards on the job, and one of the most critical aspects of their safety gear is electrical gloves. These specialized gloves are designed to protect the hands from electric shocks and burns, allowing electricians to work on or near live electrical components safely. As with any safety equipment, there’s a wide range of electrical gloves available, each designed to handle specific types of electrical work and hazards.

| Key Takeaways | Description |

|---|---|

| Hand Protection | Electrical gloves are essential for protecting electricians from electric shocks and burns during electrical work. |

| Safety Standards | Standards such as ASTM, IEC, and EN delineate the design, testing, and classification of electrical gloves, guiding electricians in selecting the proper gloves. |

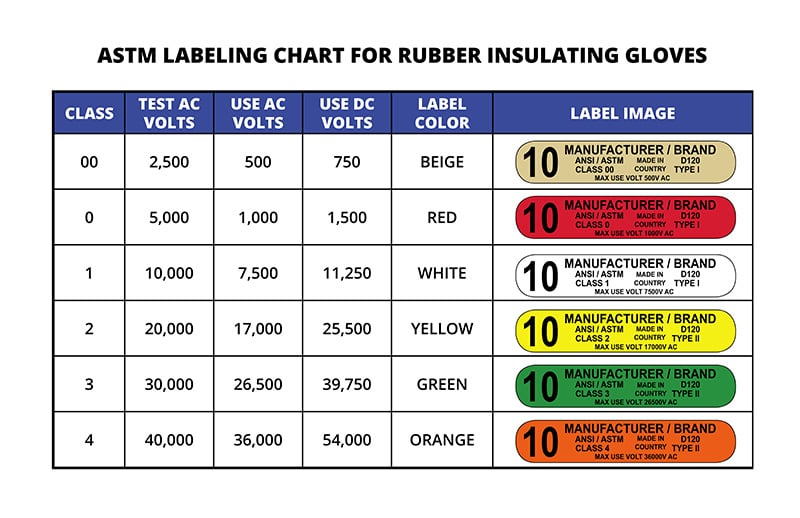

| Glove Classifications | Gloves are classified into six classes (00, 0, 1, 2, 3, 4) based on the maximum use voltage they can withstand, ranging from 500 to 36,000 volts AC. |

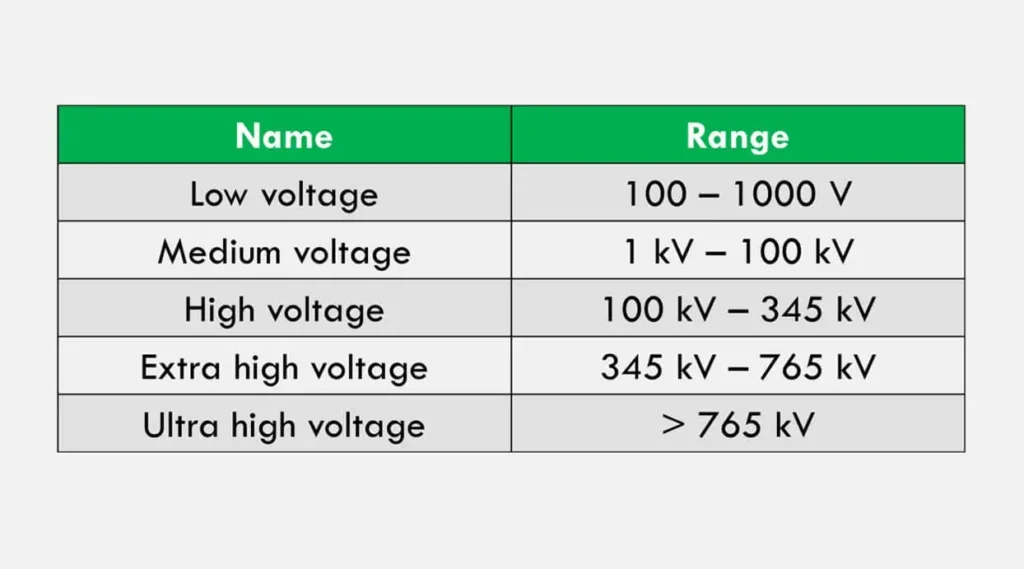

| Voltage Levels | Selection of gloves should correspond with the voltage level of work, from Class 00 or 0 for low-voltage tasks to Class 1 to 4 for medium to high-voltage systems. |

| Material and Design | Gloves are made from insulating materials like rubber, often with design features to enhance dexterity and comfort, such as a contoured shape and soft materials. |

| Complementary Safety Gear | Gloves should be part of broader safety attire, including the best work boots for men and a well-organized electrician backpack for tool management. |

| Maintenance and Care | Regular cleaning, inspection, and testing of electrical gloves are necessary to maintain their protective qualities. |

| Storage Best Practices | Gloves should be properly handled and stored in a cool, dry place away from light and ozone. |

| Beyond Gloves | A comprehensive safety approach includes wearing appropriate workwear and using professional-grade tools like the Bosch GOP18V-28N 18V Multi-Tool. |

| Educational Resources | Continuous training and updates on safety standards, as well as proficiency with tools like stud finders and voltage tester pens, enhance an electrician’s safety and skills. |

| Conclusion | Understanding and complying with safety standards for electrical gloves is crucial for electrician safety, compliance, and career longevity. |

Understanding which gloves are appropriate for various tasks is essential. For this reason, various safety standards and classifications are in place to guide electricians in selecting the right pair of gloves. In this article, we’ll explore these standards and help you understand how to ensure the safety of your hands during electrical work.

Understanding Electrical Glove Standards

Electrical safety standards are critical for ensuring that electricians have the necessary protection when working with electricity. Standards such as ASTM, IEC, and EN provide guidelines and requirements for the design, testing, and use of electrical gloves. ASTM D120, for example, is a standard specification for rubber insulating gloves, and it encompasses several tests to verify the gloves’ dielectric properties, physical strength, and durability.

Here’s a look at the classification of electrical gloves according to safety standards:

- Class 00: Rated for a maximum use voltage of 500 volts AC

- Class 0: Rated for a maximum use voltage of 1,000 volts AC

- Class 1: Rated for a maximum use voltage of 7,500 volts AC

- Class 2: Rated for a maximum use voltage of 17,000 volts AC

- Class 3: Rated for a maximum use voltage of 26,500 volts AC

- Class 4: Rated for a maximum use voltage of 36,000 volts AC

Classifications and Use Cases for Electrical Gloves

The breakdown of electrical glove classes provides a framework for electricians to choose the appropriate gloves based on the voltage levels they’ll be exposed to. Using gloves that are rated for a higher voltage than necessary can provide an additional safety margin, but can also reduce dexterity, so it’s important to find the right balance.

For example, for low-voltage work up to 500 volts AC, Class 00 gloves would be sufficient, whereas for high-voltage tasks, Class 4 gloves would be necessary to protect against up to 36,000 volts AC.

Electrical Work and Voltage Levels

When working with different voltage levels, it’s important to understand the associated risks and required protection. An electrician handling live wires or electrical panels must be adequately equipped with the right gloves for the job.

- Low-voltage systems (below 1,000 volts AC): suitable for Class 00 or Class 0 gloves.

- Medium-voltage systems (1,000 to 35,000 volts AC): suitable for Class 1 to Class 4 gloves, depending on the exact voltage.

Furthermore, ensuring the use of the best voltage tester is part of an electrician’s safety protocol to accurately determine if an electrical system is live and avoid any potential hazards.

Material and Design of Electrical Gloves

Electrical gloves are mainly manufactured from natural rubber or synthetic materials such as nitrile rubber due to their excellent insulating properties. The material not only needs to be an effective insulator but also has to provide enough flexibility and grip for the electrician to perform tasks comfortably and efficiently.

Design features contributing to safety and dexterity may include:

- Contoured shape for better hand movement

- Rolled cuffs to prevent tearing

- Soft materials for improved tactile sensitivity

Ensuring a Safe Work Environment

To maximize safety, electricians should pair their gloves with appropriate protective workwear. This includes wearing the best work boots for men in 2023 which offer protection from electrical hazards and providing good grip and comfort for standing for long periods. In addition, keeping all necessary tools and equipment within reach in a well-organized electrician backpack contributes significantly to safety and efficiency on the job.

Maintenance, Care, and Inspection of Electrical Gloves

Like any safety equipment, electrical gloves require proper maintenance, care, and routine inspections to ensure they continue to provide the intended protection. Before and after each use, gloves should be checked for any signs of wear, tear, or damage. Additionally, they should be stored correctly to prevent degradation.

Here are the basic maintenance steps for electrical gloves:

- Clean gloves using manufacturer-approved methods.

- Inspect gloves thoroughly for any damage or irregularities.

- Test gloves periodically according to ASTM F496 specifications.

Handling and Storage Best Practices

Using gloves correctly and storing them in a proper environment is crucial for maintaining their protective qualities. Best practices include:

- Handling: Always inspect the gloves for physical damage before use.

- Storage: Store the gloves in a cool, dry place away from direct sunlight and sources of ozone to prevent degradation.

Electrical Safety Beyond Gloves

While gloves are essential, they are just one component of an electrician’s overall safety protocol. Wearing the right workwear helps protect against other occupational hazards. Also, using professional-grade tools, like the Bosch GOP18V-28N 18V Multi-Tool, can enhance safety with features designed to minimize risks when cutting, sawing, or sanding in various applications.

Comprehensive Electrical Safety Toolkit

A complete toolkit is not only about the right protective gear but also having the best tools for the job at hand. This would include powerful and reliable items, such as the DeWalt 20V Max XR Impact Driver, which allows for precise and efficient work, reducing the chance of accidents due to tool failure or inadequacy.

Regular Training and Updates on Safety Standards

Keeping up-to-date with the latest safety standards and work practices is essential for electricians. Regular training can help electricians stay informed about new technologies and the latest methods for ensuring workplace safety.

Educational Resources for Electricians

Ongoing education can significantly enhance an electrician’s skills. Electricians can maximize their proficiency by understanding tools such as stud finders and practicing safe handling techniques, like the correct way to use a voltage tester pen.

Conclusion: Integrating Standards for Enhanced Safety

To sum up, proper hand protection is a must for electricians, and understanding and adhering to electrical glove safety standards is key to ensuring personal safety and compliance. Always remember to select gloves based on the specific voltage level and task requirements.

As a closing remark, it’s vital for electricians to review and follow safety standards when selecting electrical gloves and to consider the full array of safety and work gear available, such as the options found among our collection of electrical gloves. By integrating standards and staying informed, electricians can enhance their safety and ensure long-term career sustainability.

In conclusion, the significance of recognizing and conforming to the appropriate safety standards when choosing electrical gloves cannot be overstated, as it not only ensures the personal safety of electricians but also their adherence to regulatory compliance and the sustainability of their career in the long term.

1 thought on “Electrical Gloves Safety Standards: Ensuring Hand Protection for Electricians”