When you grab a 2×4 from the lumber yard, you might be surprised to learn it’s not actually 2 inches by 4 inches. This seemingly simple piece of wood has a fascinating story behind its measurements, and understanding its true dimensions is crucial for successful building projects.

| Key Point | Details |

|---|---|

| Actual Size | 1.5″ × 3.5″ |

| Standard Lengths | 8′, 10′, 12′, 16′, 20′ |

| Moisture Content | 19% or less |

| Grade Markings | Stamped on lumber |

| Common Uses | Framing, construction, DIY |

The Real Dimensions of 2×4 Lumber 📏

A standard 2×4 actually measures 1.5 inches by 3.5 inches. This difference isn’t a manufacturing error or a scam – it’s the result of a standardized process that transforms rough lumber into finished, ready-to-use boards.

Why the Size Difference?

- Raw lumber starts at true 2×4 dimensions

- Drying process shrinks wood naturally

- Planing smooths surfaces and reduces size

- Final dimensions are industry standard

Historical Context

The story of 2×4 dimensions dates back to early sawmills. Originally, rough-cut lumber was indeed 2 inches by 4 inches, but as milling techniques improved, standardization became necessary.

Evolution Timeline

- 1920s: Rough-cut lumber sold at true dimensions

- 1930s: Planing became standard practice

- 1960s: Current dimensions standardized

- Present: Universal sizing across North America

Manufacturing Process 🏭

Modern lumber production follows a precise sequence that affects the final dimensions:

| Process Stage | Effect on Size |

|---|---|

| Initial Cut | Full 2″ × 4″ |

| Drying | Slight shrinkage |

| Planing | Removes ~1/4″ per side |

| Final Product | 1.5″ × 3.5″ |

Practical Applications

When planning projects, always use actual dimensions for accurate measurements. This is especially important when:

Critical Measurements

- Calculating wall heights

- Spacing between studs

- Planning door and window openings

- Determining material quantities

For precise cutting and measuring, consider using quality tools like a laser distance meter or precision tool set.

Quality and Selection 🔍

When choosing 2×4s, look for:

Quality Indicators

- Straight grain patterns

- Minimal knots

- No visible warping

- Consistent color

- Proper grade stamp

For woodworking projects requiring precise measurements, consider using specialized cutting tools and proper measuring devices to ensure accuracy.

Measurement Guidelines 📐

Accurate measurement is crucial for successful projects using 2×4 lumber. Here’s how to get it right every time:

Measuring Best Practices

- Use a quality tape measure

- Account for saw blade thickness

- Include spacing requirements

- Consider expansion gaps

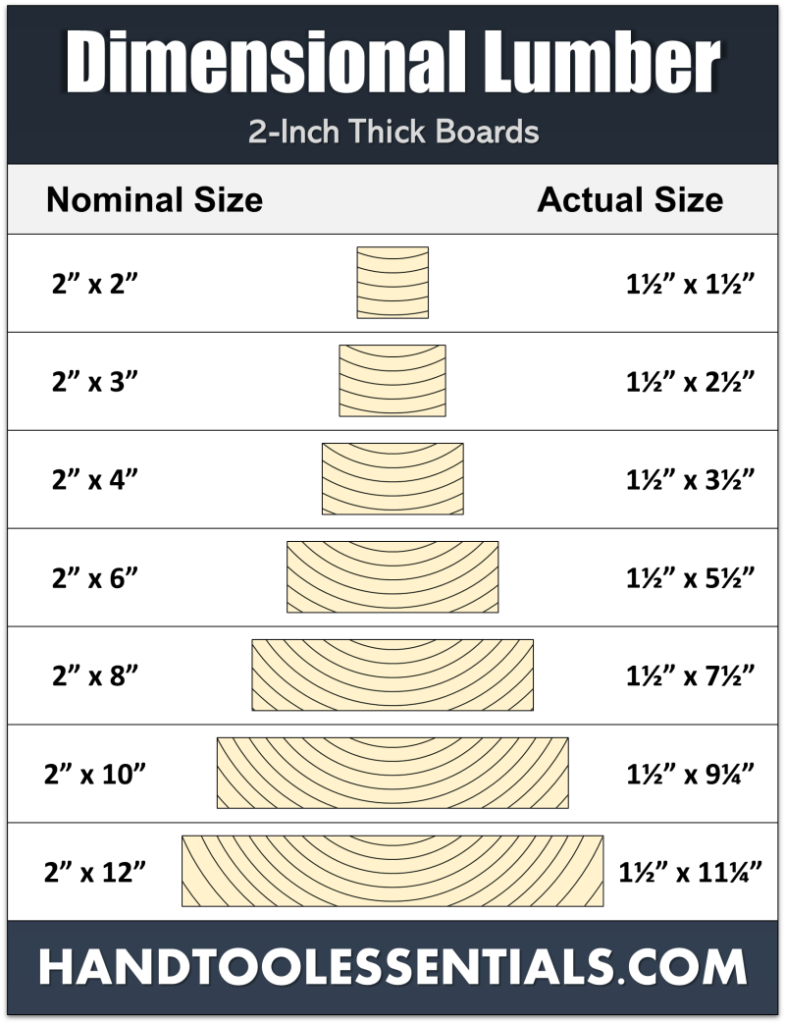

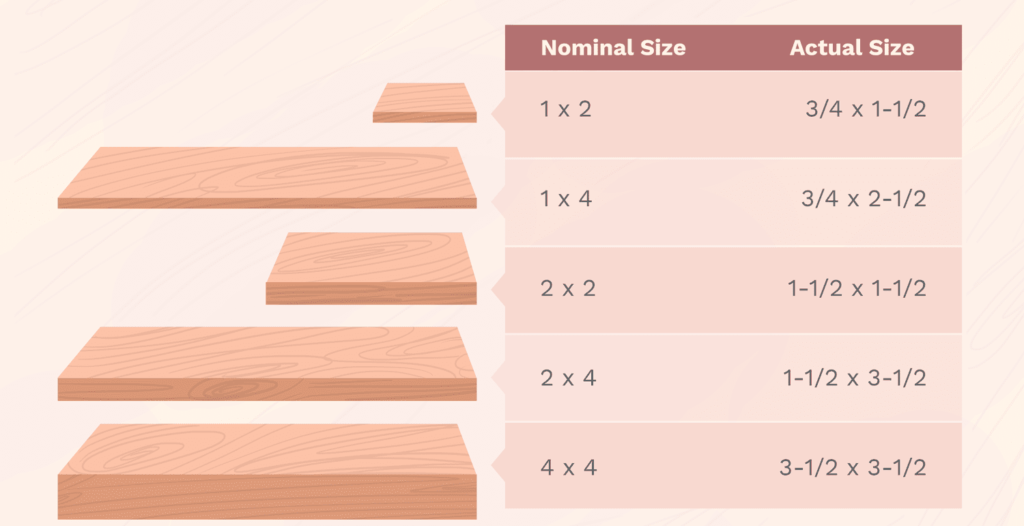

Related Lumber Sizes

Understanding 2×4 dimensions helps grasp the entire dimensional lumber system:

| Nominal Size | Actual Size | Common Use |

|---|---|---|

| 2×4 | 1.5″ × 3.5″ | Wall framing |

| 2×6 | 1.5″ × 5.5″ | Floor joists |

| 2×8 | 1.5″ × 7.25″ | Headers |

| 2×10 | 1.5″ × 9.25″ | Roof rafters |

Storage and Handling 🏗️

Proper storage prevents warping and maintains dimensional stability:

Storage Requirements

- Keep lumber dry and covered

- Stack flat on level surface

- Use stickers between layers

- Allow for air circulation

Problem-Solving Guide

Common issues and their solutions:

Troubleshooting Tips

- Warped boards: Check moisture content

- Size variations: Measure before cutting

- Splitting: Pre-drill near ends

- Rough surfaces: Light sanding needed

Project Planning

Success starts with proper planning:

Planning Checklist

- Calculate actual dimensions

- Add waste factor (10-15%)

- Consider grain direction

- Account for fastener spacing

When working with 2×4s, having the right tools makes a huge difference. Consider using:

- Quality power tools for precise cuts

- Proper safety equipment for protection

- Accurate measuring devices for layout

Industry Standards

Modern lumber standards ensure consistency:

Standard Requirements

- Maximum moisture content: 19%

- Dimensional tolerance: ±1/16″

- Grade marking required

- Treatment labeling when applicable

Future Considerations

The lumber industry continues to evolve:

Emerging Trends

- Engineered alternatives

- Sustainable harvesting

- Advanced treatment methods

- Composite materials

Expert Tips 🛠️

After years of working with dimensional lumber, here are key insights:

Pro Guidelines

- Buy extra for important projects

- Check each board carefully

- Store properly before use

- Use appropriate fasteners

Final Thoughts

Understanding the true dimensions of 2×4 lumber is fundamental for any construction or DIY project. While the naming convention might seem confusing at first, these standardized dimensions ensure consistency and compatibility across the building industry.

For specific project needs, remember to:

- Use proper measuring tools

- Follow appropriate safety guidelines

- Select the right power tools for cutting

Remember that successful projects start with understanding your materials. Whether you’re building a simple shelf or framing a house, knowing the actual dimensions of your lumber is the foundation of quality workmanship.