A jigsaw is a versatile beast, but let’s get one thing straight: finding the best jigsaw blades in 2026 isn’t about grabbing whatever’s on sale at the checkout counter. Your saw is only as precise as the blade you feed it. I’ve seen too many guys on the job site blame their saw for a “wandering” cut or a burnt edge when, 90% of the time, they were trying to force a dull, general-purpose blade through 2-inch hardwood.

Table of Contents

You aren’t going to get a cabinet-grade finish using the demolition blade you found in the bottom of your toolbox. If you want results that don’t look like they were gnawed on by a beaver, you need to match the metallurgy and tooth geometry to the material. In this guide, we break down what actually works in 2026, from the standard workhorses to the new carbide-tipped blades that survive cutting stainless steel.

The “Quick-Cut” Comparison Table

If you’re standing in the aisle of the hardware store and just need to know what to grab, here is your 2026 cheat sheet for the most common materials.

| Material | Recommended TPI | Blade Metallurgy | Top Pick (2026) | Price Range |

|---|---|---|---|---|

| Soft Wood (Clean) | 10 – 12 TPI | High Carbon Steel (HCS) | Bosch T101B | $8-12 / 5-pack |

| Hardwood (Fast) | 6 – 10 TPI | Carbide Tipped / BIM | Diablo DJT141HM | $18-25 / 3-pack |

| Sheet Metal | 18 – 24 TPI | High Speed Steel (HSS) | Bosch T118B | $10-15 / 5-pack |

| Laminate/Veneer | 10 – 14 TPI | Bi-Metal (BIM) | Bosch T101BR (Downcut) | $12-16 / 5-pack |

| Plastic/PVC | 10 – 14 TPI | Bi-Metal (BIM) | Milwaukee 48-42-5020 | $9-14 / 5-pack |

| Ceramic Tile | Grit (No teeth) | Carbide / Diamond | Bosch Expert T130RF | $15-22 / 3-pack |

| Stainless Steel | 20 – 24 TPI | Carbide Tipped | Hilti SPX 59 / Diablo | $20-30 / 3-pack |

| Scroll/Curves | 10 – 20 TPI | HCS or BIM | Bosch T119BO | $8-12 / 5-pack |

Decoding the Blade: The Technical Basics

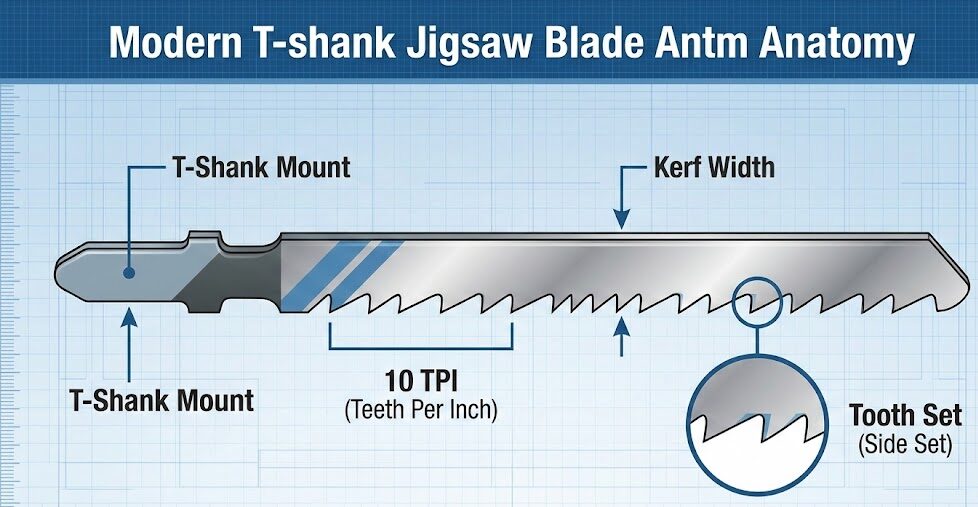

Before buying a 50-pack variety set, you need to understand the “Big Three” of jigsaw blade anatomy: the shank, the teeth, and the metal.

1. Shank Styles: T-Shank is the Standard

In 2026, the T-Shank (or Bayonet mount) is the universal industry standard. It allows for tool-less blade changes and provides a much tighter grip than the old-school U-Shank. Unless you are running a vintage saw from the 1980s, stick exclusively to T-Shank blades to avoid deflection and slippage.

Quick Check: If your jigsaw has a lever or collar that you twist without tools, it’s T-Shank compatible. If you need an Allen wrench to change blades, you’re stuck with U-Shank (consider upgrading your saw).

2. TPI (Teeth Per Inch) & Kerf

- Low TPI (6–10): These have big “gullets” to clear sawdust fast. They cut aggressively but leave a rough edge. Perfect for plunge cuts in framing lumber.

- Medium TPI (10–14): The “Goldilocks zone” for general woodworking. Fast enough for production work but clean enough for visible cuts.

- High TPI (14–36): These cut slowly but leave a polished finish. In metal, you need high TPI to ensure at least three teeth are always in contact with the material to prevent snagging and tooth breakage.

- Kerf Width: A wider kerf (the thickness of the cut) provides stability for straight lines, while a narrow kerf is essential for scroll cutting intricate curves in plywood or MDF.

3. Metallurgy: HCS vs. Bi-Metal vs. Carbide

The material your blade is made from determines its lifespan, flexibility, and what it can cut without self-destructing.

- HCS (High Carbon Steel): Flexible and cheap. Great for softwoods and curves, but dulls quickly on hardwoods or abrasive materials. If you hit a nail, you’re done.

- HSS (High-Speed Steel): Harder than HCS, designed specifically for metal cutting. Brittle, so don’t use it on wood—it will snap.

- Bi-Metal (BIM): The industry workhorse. It welds hard HSS teeth onto a flexible HCS body, giving you durability without brittleness. This is the “90% solution” for most jobs.

- Carbide-Tipped: The new performance king in 2026. While a Bi-Metal blade might dull after three cuts in stainless steel, a Carbide blade like the Bosch Expert or Diablo Carbide series can last up to 50 times longer. Yes, they cost 3x more, but the math works out if you’re a pro.

- Carbide Grit (Toothless): Used for tile, fiberglass, and cast iron. No teeth—just abrasive particles bonded to the edge. Slow, but it’s the only option for ceramics.

Best Jigsaw Blades by Material (2026 Picks)

Here’s where we get specific. These are the blades that professionals actually keep in their trucks, not the ones that come free with your saw.

Best for Clean Wood Cuts: Bosch T101B

Price: $8-12 for a 5-pack | TPI: 10 | Material: HCS

If you are cutting cabinetry or trim, you can’t afford tear-out. The T101B features taper-ground teeth that act like tiny knives rather than saws. It leaves a finish so smooth it rarely needs sanding.

Pros:

- Near-zero splintering on cross-cuts

- Clean bottom edge (important for visible underside cuts)

- Affordable enough to replace frequently

Cons:

- Slower than aggressive blades

- Dulls quickly on hardwoods like oak or maple

- Not suitable for thick stock (over 1.5 inches)

Best For: Furniture making, finish carpentry, plywood projects

- Ideal for precise cuts on laminate and vinyl floors, including reinforced vinyl floors.

- Cutting capacity for materials with thicknesses from 1.5mm to 15mm.

- Carbide technology on the teeth, ensuring greater strength and durability.

- Against targeted teeth for clean cuts on both sides of material.

- Compatible with all universal T-fit jigsaw saws.

Pro Tip: Turn off your saw’s orbital action completely for the cleanest results. Orbital mode adds speed but sacrifices finish quality.

Best for Hardwood & Demolition: Diablo DJT141HM Carbide

Price: $18-25 for a 3-pack | TPI: 8 | Material: Carbide-Tipped Bi-Metal

Hardwoods like Oak, Ipe, or reclaimed lumber will destroy standard steel blades within minutes. The Diablo Carbide-Tipped blade is built for punishment. It can hit a stray nail embedded in old barn wood and keep cutting without losing a tooth—a must-have for flooring installers and demolition crews.

Pros:

- Cuts hardwood 10x faster than HCS blades

- Survives hitting nails, screws, and staples

- Lasts weeks instead of hours under heavy use

Cons:

- Expensive upfront cost

- Aggressive cut leaves rougher edges than precision blades

- Overkill for softwoods

Best For: Hardwood flooring, demolition work, cutting reclaimed lumber

- Extended Cutting Life - Achieve up to 50X longer blade life with high-performance carbide teeth, delivering superior durability for extended use across wood, metal, and plastic materials.

- Effortless Cutting - Aggressive tooth geometry provides fast, smooth cuts, minimizing resistance and enhancing ease of use in both cordless and corded jig saws.

- Reduced Heat Buildup - Optimized blade design with Perma-SHIELD non-stick coating prevents heat and pitch build-up, ensuring cool, efficient cutting for demanding applications.

- Exceptional Impact Resistance - Reinforced carbide tip connection adds extreme durability, enabling high impact resistance and precision in challenging cuts.

- Universal Compatibility - T-shank design fits all combo and most U-shank jig saws, allowing versatile use with a wide range of power tools.

Best for Metal Cutting: Bosch T118B (Sheet Metal) & Hilti SPX 59 (Stainless)

Price: $10-15 for 5-pack (T118B) | $20-30 for 3-pack (Hilti SPX 59) | TPI: 18-24 | Material: HSS / Carbide

Sheet metal and aluminum require at least 18 TPI to prevent the teeth from snagging and ripping out. The Bosch T118B is the industry standard for HVAC ductwork and thin-gauge steel. For stainless steel or thick metal (up to 1/4″), you need to step up to carbide-tipped blades like the Hilti SPX 59 or Diablo’s metal-cutting carbide line.

Pros:

- Cuts 18-gauge steel without chattering or bending

- HSS teeth stay sharp through aluminum and copper

- Carbide versions handle stainless and hardened steel

Cons:

- Slow cutting speed (by design—rushing causes breakage)

- Requires cutting oil or lubricant for thick stock

- Carbide blades are expensive and unnecessary for thin metal

Best For: HVAC installation, automotive body work, metal fabrication

- For medium to thin metals 1/8 In. to 1/4 In. thick (ferrous and non-ferrous)

- 11-14 TPI progressive tooth design for smooth cuts in various thicknesses

- High-speed steel construction for maximum life in straight cuts

- 3-5/8 In. overall length, 2-5/8 In. working length

- Proper lubricant is recommended when cutting metal

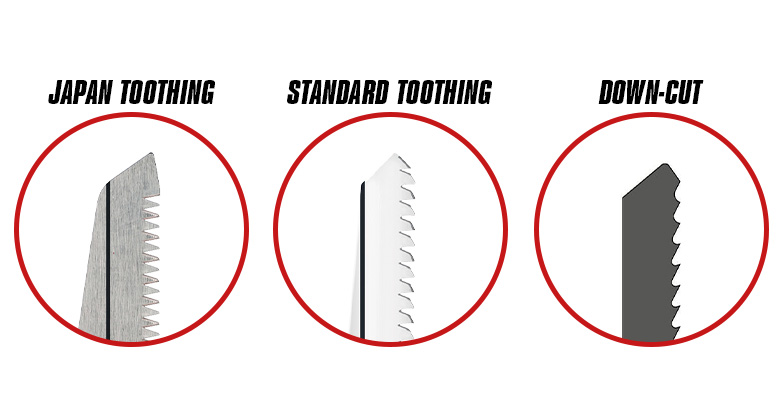

Best for Laminates & Veneer: Bosch T101BR (Downcut)

Price: $12-16 for a 5-pack | TPI: 12 (Reverse) | Material: Bi-Metal

Standard blades cut on the upstroke, which shatters the delicate top layer of laminate countertops or veneered plywood. A reverse-tooth (Downcut) blade like the T101BR pushes the material down, ensuring the “show side” remains perfectly crisp with zero chipping.

Pros:

- Eliminates top-surface chipping on laminate

- Works beautifully on melamine and pre-finished plywood

- Bi-metal construction prevents premature dulling

Cons:

- Requires firm downward pressure (blade wants to lift the saw)

- Not suitable for general woodworking

- Slightly slower than standard upcut blades

Best For: Kitchen countertop installers, cabinet makers, furniture restoration

- The information below is per-pack only

- 10 TPI variable-pitch tooth pattern for clean cuts in hard and soft wood, plywood, plastics, OSB, laminated particle board 3/16 In. to 1-1/4 In. thick

- High carbon steel construction for long life in wood materials

- 4 In. overall length, 3 In. working length

- 3 piece pack

Warning: Hold your saw down firmly when using downcut blades. The reverse teeth naturally want to push the saw away from the workpiece, which can cause the blade to jump if you’re not prepared.

Best for Plastic & PVC: Milwaukee 48-42-5020 Bi-Metal

Price: $9-14 for a 5-pack | TPI: 10-12 | Material: Bi-Metal

Cutting PVC pipe or acrylic with the wrong blade causes melting, not cutting. You need a blade with medium TPI and aggressive gullets to clear the “plastic chips” before they re-weld. The Milwaukee Bi-Metal line is specifically designed for this.

Pros:

- Prevents melting and gumming in PVC and acrylic

- Fast cutting speed without edge melting

- Durable enough for fiberglass and composite materials

Cons:

- Leaves rougher edges than fine-tooth blades

- Not ideal for very thin plastic sheets (use higher TPI)

Best For: Plumbing, acrylic fabrication, cutting plastic laminates

- Power Tools

- Made by: Milwaukee

- Country of Manufacturing: Switzerland

- 18 TPI, 2-3/4 in. Length, High Speed Steel Construction

- 9/32 in. Width, Universal Shank

Best for Ceramic Tile & Masonry: Bosch Expert T130RF Carbide Grit

Price: $15-22 for a 3-pack | TPI: N/A (Grit) | Material: Carbide Grit

Ceramic tile will instantly destroy any toothed blade. The T130RF uses bonded carbide grit instead of teeth, essentially turning your jigsaw into a slow grinder. It’s the only way to cut tile, cement board, or cast iron with a jigsaw.

Pros:

- Only viable option for cutting porcelain or ceramic tile

- Also works on fiber cement siding (Hardie board)

- Surprisingly long lifespan if used correctly

Cons:

- Extremely slow—expect 1-2 inches per minute

- Requires constant water cooling to prevent cracking tile

- Creates massive amounts of dust (wear a respirator)

Best For: Tile installers, bathroom remodels, cutting sink holes in tile countertops

- Designed for straight cuts in tiles and ceramics

- Tungsten Carbide Grits for Long Use

- Very flexible carbon steel body (HCS)

- Cuts soft ceramic with thickness of 5-15mm

- Compatible with T-Fit Jig Saws

Pro Tip: Use a spray bottle to keep the cut line wet. The water cools the blade and prevents the tile from cracking due to heat stress.

Best for Scroll Cuts & Curves: Bosch T119BO Narrow Body

Price: $8-12 for a 5-pack | TPI: 12 | Material: HCS

Tight radius curves in plywood or MDF require a narrow blade body (under 0.1 inches wide). The T119BO is purpose-built for scrollwork, intricate cutouts, and tight-radius curves that would snap a standard blade.

Pros:

- Cuts curves as tight as 1-inch radius

- Thin kerf reduces material waste

- Flexible enough to follow complex patterns

Cons:

- Too flexible for straight cuts (will wander)

- Dulls quickly on hardwoods

- Fragile—don’t force it or apply side pressure

Best For: Craft projects, making Christmas ornaments, cutting lettering in wood signs

- GINEPAN Jigsaw Blades T Shank are made of High-Carbon steel through multiple processes such as quenching/burning/returning/Grinding, making the jig saw blades more durable.

- T119BO Jigsaw Blade Optimized for Curved & Scrolling Fast Cuts of wood and wood products 5 /16 In. to 1/4 In. thick. 12 TPI tooth profile and high carbon steel blade body produce fast results

- T-shank design fits over 95 percent of current jigsaws. Such as : Compatible with DEWALT, GINEPAN, Bosch, BLACK and DECKER, TOOLDO, Makita, SKIL, Ryobi and Rockwell BladeRunner x2 jigsaw blades

- Factory direct price! GINEPAN T Shank jigsaw blade provide the best cost but remain in great quality.

- 20 Piece GINEPAN universal T119BO jigsaws jig saw blades accessory kit with case. (Warm tips: Since the attached Case is compatible with most saw blades, the gap is relatively large. T119BO saw blade is small, easy to scatter in the Case, but does not affect the use)

Pro Tips for Better Cutting

Even the best blade won’t save you if you’re using bad technique. Here are the tricks that separate professionals from frustrated homeowners.

The Splinter Guard Trick

Before cutting finished plywood or veneer, apply blue painter’s tape along your cut line on both the top and bottom surfaces. The tape supports the wood fibers during the cut and prevents blow-out on the exit side. This is especially critical when cutting Baltic birch or any pre-finished material where you can’t sand out mistakes.

Bonus: The tape also gives you a visible guideline that won’t blow away like pencil dust.

Master Your Orbital Action Settings

Most modern jigsaws have an orbital action dial (0-3 or 0-4). Here’s when to use each setting:

- Turn Orbital Action UP (3-4) for:

- Fast rip cuts in construction lumber

- Thick softwoods (2x4s, 2x6s)

- When speed matters more than finish quality

- Turn Orbital Action DOWN or OFF (0-1) for:

- Any metal cutting (prevents tooth breakage)

- Tight curves and scroll work

- Finish cuts in cabinetry or trim

- Cutting tile or masonry (prevents cracking)

Think of orbital action like turbo mode on a car: great for the highway, terrible for parallel parking.

Let the Saw Do the Work

The number one mistake is “pushing” the jigsaw forward. This causes blade deflection (bending), which creates angled cuts and premature blade failure. Instead, guide the saw gently and let the blade’s speed do the cutting. If you find yourself leaning on the saw, either your blade is dull or you’re using the wrong TPI for the material.

Use a Sacrificial Backer Board

When cutting thin materials like sheet metal or veneer, clamp a piece of scrap plywood underneath. This prevents the material from vibrating and gives the blade something solid to cut against, resulting in cleaner edges and less noise.

Mark Your Blade Usage

Professional cabinet shops write the material and date on each blade with a Sharpie before storing them. This prevents accidentally using a metal blade on wood (which will instantly dull it) or a dull blade on a finish cut. A 30-second label saves hours of sanding.

Blade Lifespan: Budget vs. Premium—Does Price Really Matter?

Does a $15 blade really beat a $3 one? In 2026, the answer is a resounding yes if you value your time. Here’s what you actually get at each price tier:

HCS Budget Blades ($5-8 per 5-pack)

Expected Lifespan: 5–10 feet of clean cutting in pine before it starts “smoking” the wood.

Best For: Homeowners doing occasional weekend projects. If you cut wood once a month, these are fine.

Warning Signs to Replace:

- Burning smell or scorch marks on cut edges

- Saw requires more force to push forward

- Cut line starts to wander or angle

Bi-Metal Mid-Range Blades ($10-15 per 5-pack)

Expected Lifespan: Can handle a full weekend project or 2-3 weeks of moderate job-site use.

Best For: Serious DIYers and weekend contractors who need reliability without breaking the bank.

The Sweet Spot: This is where 90% of users should live. Brands like Bosch, DeWalt, and Milwaukee all make excellent Bi-Metal blades in this range.

Carbide Premium Blades ($18-30 per 3-pack)

Expected Lifespan: 10-50x longer than standard blades in abrasive materials. One blade can last an entire month of daily professional use.

Best For: Professional contractors, flooring installers, anyone cutting hardwoods or abrasive materials daily.

The Math: A $25 carbide blade that lasts 50 cuts vs. 10 standard blades at $2 each ($20 total). You’re not just saving money—you’re saving the time spent changing blades mid-job.

Warning: Carbide blades are overkill for cutting pine 2x4s. Save them for the jobs that destroy regular blades.

Frequently Asked Questions

Can I use a jigsaw blade on tile?

Yes, but only with a carbide-grit or diamond-coated blade like the Bosch Expert T130RF. Standard toothed blades will shatter ceramic tile instantly and potentially send sharp fragments flying. You’ll also need to keep the cut wet with a spray bottle to prevent heat cracking, and expect slow progress—cutting tile with a jigsaw is a last resort when a tile saw isn’t available.

How often should I change my blade?

Replace your blade immediately if you notice any of these warning signs: a burning smell or scorch marks on the wood, excessive vibration or chattering during the cut, the saw requiring significantly more force to move forward, or visible damage like missing teeth or a bent blade. For professional use, many contractors replace blades daily regardless of visible wear to maintain consistent cut quality.

Are all jigsaw blades universal?

No. There are two main shank types: T-Shank (the modern standard, used by 95% of jigsaws made after 2000) and U-Shank (found on older models and some budget saws). Always check your saw’s manual, but if your saw has tool-less blade changing, it’s almost certainly T-Shank. The good news is that T-Shank blades are far more widely available and offer better grip and performance.

What does “Progressive Tooth” mean?

A progressive tooth blade (like the Bosch Progressor series) has small teeth near the shank and gradually larger teeth toward the tip. This design allows one blade to cut both thin materials (where small teeth prevent snagging) and thick materials (where large teeth provide aggressive cutting) effectively. It’s the ultimate “all-rounder” blade for a messy toolbox where you don’t want to carry 12 specialized blades.

Why is my blade bending mid-cut?

This is called deflection, and it has three main causes. First, you may be forcing the saw forward too fast instead of letting the blade’s speed do the work. Second, you might be using a blade that’s too thin or flexible for the thickness of material you’re cutting. Third, your blade may be dull and needs replacement. The solution: switch to a “Precision” or “Progressor” series blade (which is thicker and more rigid), reduce your forward pressure, and ensure orbital action is turned down or off.

Do more expensive blades really make a difference?

Absolutely, but only if you’re using them correctly. A $25 carbide blade will transform your experience cutting hardwoods, tile, or metal—lasting 10-50 times longer than a $3 blade. However, if you’re just cutting pine boards for a weekend deck project, a mid-range Bi-Metal blade is perfectly adequate. The key is matching the blade quality to the job difficulty. Premium blades aren’t marketing hype; they use better steel, tighter tolerances, and advanced tooth geometry that you can feel in the cut quality.

Can I sharpen jigsaw blades?

Technically yes, but practically no. Jigsaw blades are so inexpensive and the teeth are so small that sharpening them is more trouble than it’s worth. Professional sharpening services exist for expensive circular saw blades and router bits, but jigsaw blades are considered consumable items. When they’re dull, recycle the metal and install a fresh blade. Your time is worth more than the $2 you’d save.

The Bottom Line: Your Next Step

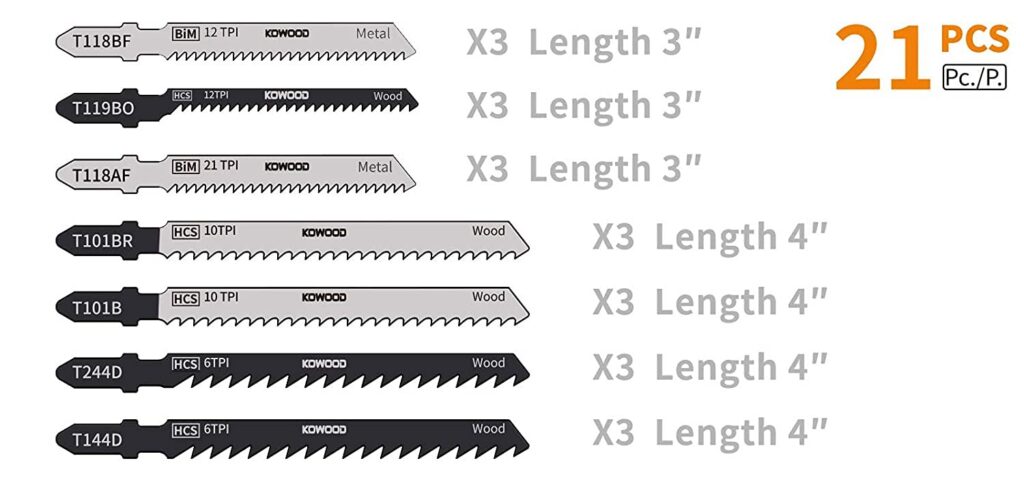

Stop buying those 50-piece “variety packs” filled with mystery blades that you’ll never use. Those sets are designed to look like a good deal but consist mostly of duplicates and low-quality filler. Instead, build a focused collection based on the materials you actually cut.

The Essential Starter Kit (for most users):

- Bosch T101B (5-pack) – For clean wood cuts and finish work

- Bosch T144D (5-pack) – For fast, rough cuts in construction lumber

- Bosch T118B (5-pack) – For sheet metal and aluminum

- One carbide-tipped blade (Diablo or Bosch Expert) – For “the inevitable hardwood or mystery material”

Total Investment: $40-50 for blades that will handle 95% of home and job-site tasks.

A $15 premium blade will make your $60 jigsaw perform like a $300 professional tool. That’s not marketing speak—that’s metallurgy. The blade is the only part of your saw that actually touches the material, so it’s the only part that truly determines cut quality.

Remember: The right blade doesn’t just cut faster—it cuts safer. A sharp, appropriate blade requires less force, which means better control and fewer accidents.